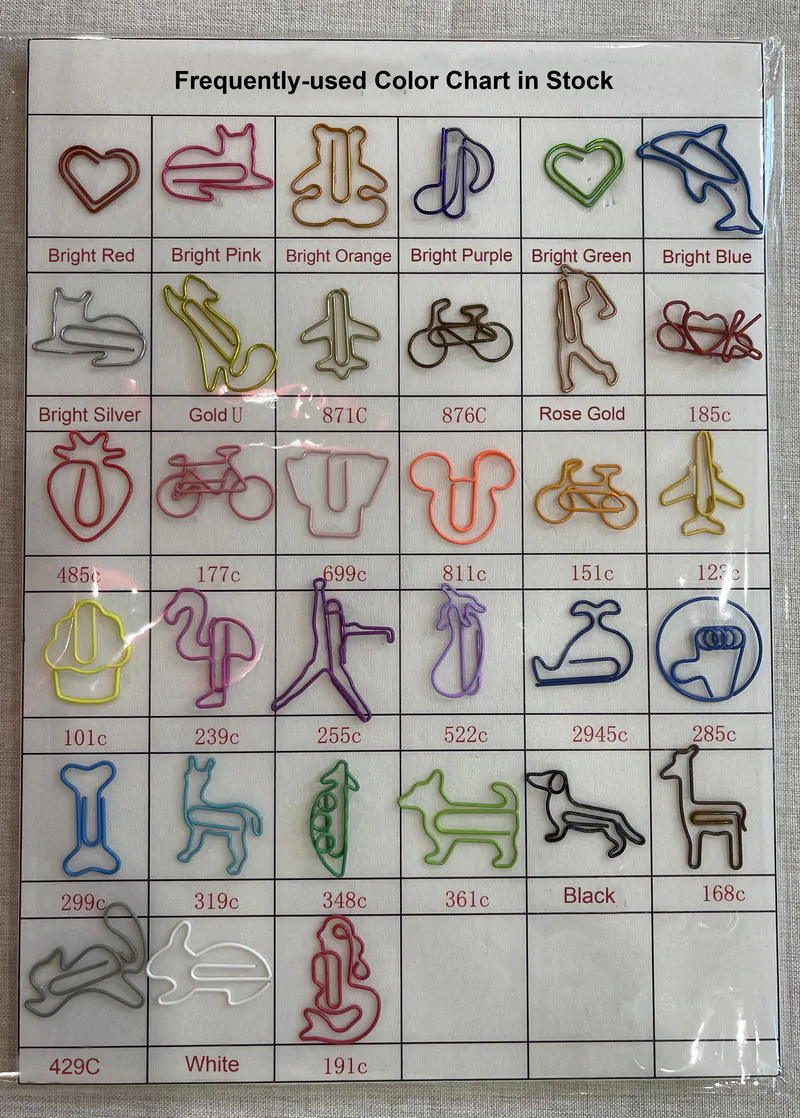

We offer various color options for custom-designed paper clips :

- Colors of the plastic coating

- Colors of the plastic coating

- Electroplating colors

- Rainbow coating

- Electrophoretic paint

- Metallic colors

- Printing inks

- Color contrast in practical application

- The colors of molded or printed paper clips are typically matched to the Pantone Matching System (PMS) color chart to ensure a perfect match. We also offer electroplating, oxidizing, and electrophoretic coloring, which generally results in a higher gloss. Minimum order quantities may vary depending on the material and surface treatment process.

- 1. Colors of the plastic coating

- Strictly speaking, we now use plastic spray coatings, the production of which is comparatively complex. This process is also known as electrostatic powder coating. Plastic powder is sprayed onto the iron surface of paper clips, giving them a protective and decorative effect. The paper clips are then placed in an oven at a specific temperature. The powder melts under the high temperature, spreads evenly, and finally solidifies into a powdered plastic coating.

- Vinyl-coated, molded paper clips consist of a wire (usually iron, steel, or brass) with a vinyl or plastic coating. They are corrosion-resistant, non-slip, and protect delicate surfaces from scratches. Available in various colors for better organization, they are sturdy but slightly less robust than uncoated clips and are ideal for holding papers together or for light crafting.

- The most common method for processing our orders is plastic coating. It would be more convenient and economical to use the frequently used colors from our color chart (see below). The minimum order quantity is 3,000 to 5,000 pieces if you accept similar colors to those listed below that most closely match your target color. Smaller quantities are possible, but an additional setup fee will apply.

- If it is a completely new and rare PMS color, we will need approximately 4,000 to 50,000 pieces per color, unless you pay a surcharge for color matching. To ensure you can accept this quantity, please contact us beforehand.

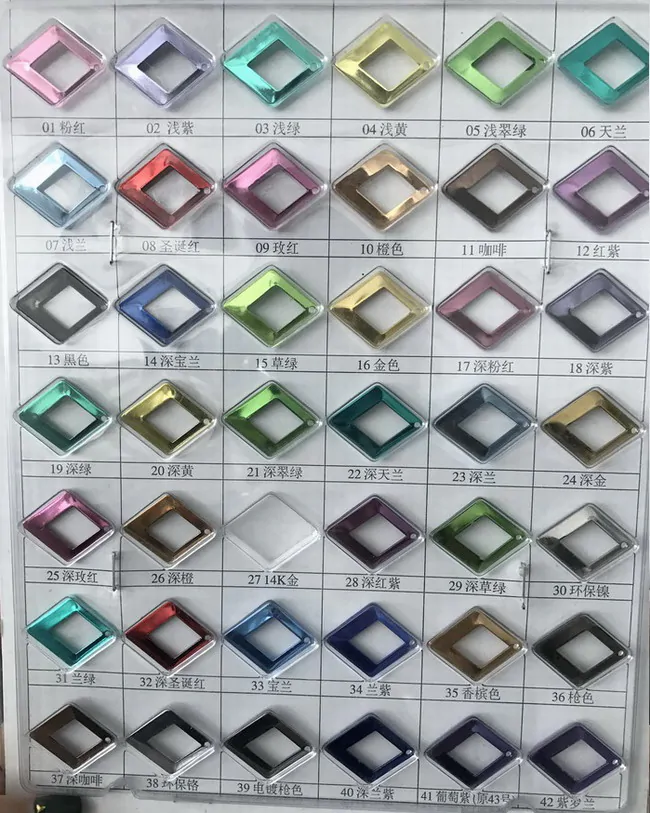

- 2. Baking colors

- Stoved enamel coating is a common coating technology used in the production of custom-shaped paper clips. It provides an attractive and durable finish. The basic principle involves spraying the enamel onto the wire or metal surface of the paper clips and then curing them in a high-temperature oven. This makes the coating robust and resistant, and also offers improved corrosion protection and abrasion resistance. Its properties include:

- Rich colors – almost any color can be mixed, from solid colors to gradients and metallic tones.

- Surface finish – The gloss level can vary (glossy, satin, matte), the feel is smooth.

- Protection – The coating protects against rust and scratches, thus increasing durability.

- For shaped paper clips, baked enamel offers both an attractive appearance and good practicality, making it particularly suitable for decorative purposes, ideal for stationery sets, children's products or DIY crafts.

- You can have any Pantone color number for stoving enamels custom-matched using the Pantone catalog. The minimum order quantity for stoving enamels is typically 5,000 pieces . Custom stoving enamels incur additional costs for color matching. If color is not critical for your project, we recommend using the standard colors from our collection due to the significantly higher cost of custom stoving enamels.

- Color selection for baked enamel finishes is more flexible than for plastic coatings. Custom color matching of plastic-coated cables typically requires a high minimum order quantity of several tens of thousands of pieces, while the minimum order quantity for baked enamel paper clips can be significantly lower. Therefore, it is more practical, efficient, and economical to select the closest matching number from our color chart that corresponds to your desired shade.

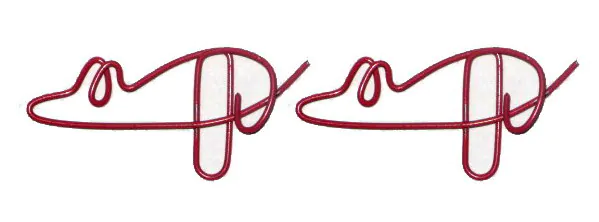

- 3. Electroplating paints

The electroplated finish has a very glossy appearance. In the electroplating process, wire paper clips are immersed in an electrolyte containing metal ions. Electrolysis then occurs through the application of an electric current. The metal ions are reduced to metal atoms and deposited on the surface of the iron wire, creating a metallic coating. Electroplating can improve the appearance of paper clips, increase their resistance to corrosion and abrasion, and extend their lifespan.

- Compared to other colors, these coatings generally appear shinier and more elegant. They typically include electroplated silver, (imitation) gold, rose gold, black, red, green, blue, etc.

- Regarding the desired effect, gold, rose gold, silver, and black are best suited, as these colors appear more uniform and stable, while the other colors can sometimes appear somewhat uneven due to their properties. The minimum order quantity for electroplated clips is typically 5,000 pieces . The cost depends on the specific requirements for the electroplating colors and technologies. Barrel plating generally does not result in a significant cost increase, while rack plating is usually more expensive. The cost of electroplating green, purple, blue, and retro colors is also somewhat higher than for other colors due to the potentially higher reject rate in case of uneven coloring.

- For paper clips with an open structure, coloring typically requires rack electroplating. In this process, the uncolored clips are individually suspended on racks, as they would otherwise become entangled during the coloring process. This additional effort for coloring affects the final price.

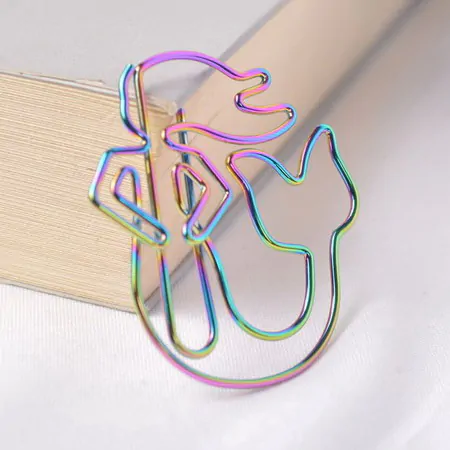

- 4. Rainbow coating

- Rainbow coating, also known as iridescent coating or PVD rainbow coating, is typically achieved through physical vapor deposition (PVD). A very thin layer of metal or compound coating (e.g., titanium nitride) is applied to the wire surface of shaped paper clips. The principle of light interference creates a rainbow-like color gradient. This improves the abrasion and corrosion resistance of the paper clips, extends their lifespan, and enhances the aesthetics of custom-designed paper clips. Its properties include:

- Color effect – A multicolored gradient is displayed, similar to a rainbow, which naturally transitions from red to violet, with certain hues changing depending on the angle of the light.

- Texture – Retains a metallic sheen and is characterized by high hardness and wear resistance.

- Environmental friendliness – The PVD process is cleaner than conventional electroplating and produces less waste.

- A rainbow coating transforms beautifully designed paper clips into attractive little accessories that combine technical sophistication with artistic appeal. These star- or flower-shaped paper clips with a rainbow coating display dynamic color changes and are therefore perfect for creative stationery, gifts, or collectibles. Depending on the light, the colors shift from blue to gold to violet, creating a stunning visual effect. They are particularly suitable for applications requiring a high-quality feel, such as branded merchandise or design exhibitions .

- 5. Electrophoretic paint

- Electrophoretic coating (e-coating) is a modern surface treatment technology in which charged color particles are applied to the surface of conductive objects (e.g., metal or wire paper clips) using an electric field. This creates a uniform and durable coating. It is widely used for coating industrial and everyday objects, improving both their appearance and protection.

- Electrophoresis vs. electroplating for shaped paper clips

- Appearance : Electrophoresis creates a lacquered look with more vibrant colors; electroplating produces a shiny, metallic surface.

- Cost : Electrophoresis is generally more economical for various colors; electroplating is more expensive and suitable for a high-quality appearance.

- Method : Electrophoresis is well suited for complex shapes, as it allows for a uniform coating; however, gaps can occur with delicate designs.

- 6. Metallic colors

- Some of our customers reject coated, plated, or lacquered paper clips, or those with custom-made, open-structure paper clips that tend to tangle easily. In these cases, we typically use stainless steel or raw brass wire . Raw iron wire rusts easily, so stainless steel is the better choice. Raw brass wire, on the other hand, would oxidize and turn black due to a reaction with copper oxide .

- 7. Printing inks

- For custom-printed paper clips and binder clips, colors can be produced similarly to vinyl coatings. They can be matched to the Pantone color palette according to customer specifications. Various printing methods are available: screen printing, transfer printing, UV printing, etc.

- Regarding printing colors for stainless steel paper clips, please send us your logo so we can check if printing is possible, how many colors are needed, and whether the colors will fade after printing. Alternatively, we can also produce printed paper clips by applying a label with your logo to the stainless steel clips.

- In summary, this represents the general distinction and allocation of colors and quantities. We also offer mixed colors, provided your order meets our requirements regarding quantity or stock levels of materials or colors. Therefore, please contact us if you have any specific requests regarding your order.

- Color contrast in practical application:

- Plastic coating – Plastic-coated paper clips are characterized by bright colors, a soft feel and a low price, however the coating is thicker and tends more towards a practical style.

- Stoved enamel coating – Stoved enamel paper clips are available in various colours with optional gloss levels; the coating is thinner but less wear-resistant than a plastic coating.

- Electroplating – This process is suitable for various metals and gives them a shiny, metallic appearance. Rack plating for shaped paper clips is more expensive than barrel plating.

- Rainbow plating (PVD) – High-quality color gradients with great hardness, but without the softness of a plastic coating.

- Electrophoresis – It produces uniform, permanent colors, but is a more complex process than plastic coating.

- Oxidation – Best suited for aluminium-shaped paper clips, offering a metallic feel with high durability, but with a limited colour selection.

German View

German View French View

French View Japanese View

Japanese View